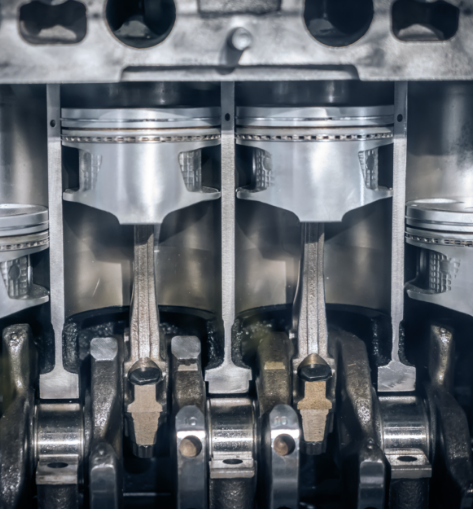

The Israel Institute of Materials Manufacturing Technologies (Formerly “The Israel Institute of Metals”) is a research & development center operating under the Technion R&D Foundation LTD. (owned by Technion)

IMT conducts applied research in the field of advanced materials processing and is working mainly with industries (in Israel and abroad), focusing on implementation of new technologies in the supply chains