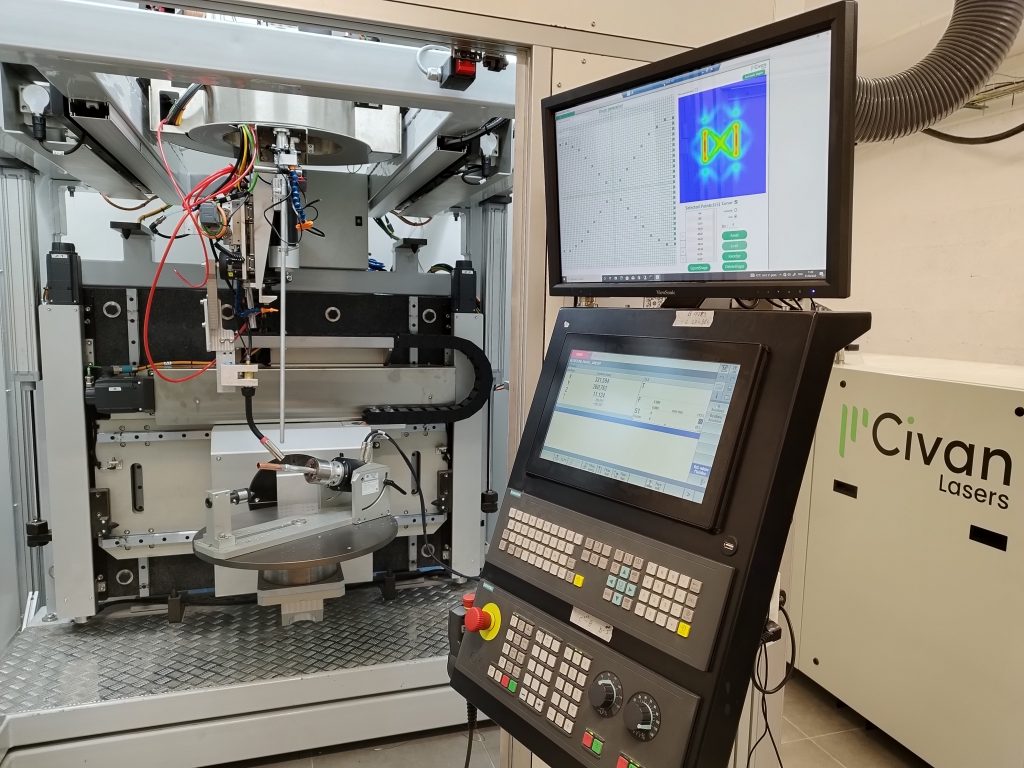

The new laser laboratory at the Israel Institute of Materials Manufacturing Technologies, created as part of the LAMP consortium, is equipped with the most powerful and advanced laser in Israel in the field of material processing. It is a dynamic beam laser from Civan company with a power of 14 kilowatts, making it one of the world’s best and most powerful laser devices.

Laser welding has many advantages over traditional soldering methods, including a 100% acceleration of the process and saving about 90% of the required energy. The technology is based on the interference of a large number of laser beams, each of which has digital control over amplitude and phase parameters.

The technology allows the creation of a unique laser beam with degrees of freedom that surpasses today’s known laser material processing technologies. This will improve control over physical processes during laser processing, such as solidification and cooling rates, laser penetration depth, and melt pool stability.

In collaboration with Bakara Geva an advanced control system was created in the form of a six-axis mechanism that combines very high mechanical speed and precision. The laboratory is equipped with a thermal imaging camera and a high-speed camera, allowing real-time monitoring of the process.

We provide fundamental, strategic, and applied research in the field of welding science and engineering. Our team is well experienced in supervising and advisory services. Our focus is laser technology and manufacturing applications such as welding, drilling, cutting, cladding, surface hardening, and surface treatment.